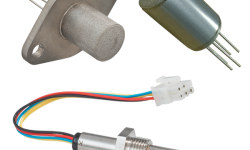

MTCS2601 Used for Argon Concentration Detection during Argon Welding

Argon arc welding is a welding technology based on general arc welding principle that uses argon to protect metal welding material and melts welding material into liquid on the base material through high current so as to form a weld pool, to let weld metal and welding material achieve metallurgical bonding. In a nutshell, it is…