Introduction

With technological advancements and a growing focus on environmental protection, it is a priority to control pollutant emissions. Measuring the flue gas humidity from fixed pollution sources is crucial for determining dry-basis oxygen content and calculating pollutant concentrations. However, the high temperature and dust content of wet flue gas, along with the significant variations in emissions from industrial sites like power plants, petrochemical facilities, waste incinerators, and steel mills, make global humidity measurement challenging. Online detection is difficult, and currently, limiting current zirconia oxygen sensors is the primary method used for high-temperature humidity measurement. In this blog, we will share the application of limiting current oxygen sensors in high-temperature flue gas humidity meters and explain how they work.

Table of Content

1. What is the Limiting Current Zirconia Oxygen Sensor?

2. How Does Limiting the Current Zirconia Oxygen Sensor Work?

3. Features of Limiting Current Zirconia Oxygen Sensor

4. Isweek Limiting Current Type Zirconia Oxygen Sensor SO-E2-250/960

1. What is the Limiting Current Zirconia Oxygen Sensor?

A Zirconia-based limiting current oxygen sensor is a device used to measure the concentration of oxygen in various environments, such as exhaust gases in combustion engines, industrial processes, and environmental monitoring. It operates based on the electrochemical properties of Zirconia (zirconium dioxide), a ceramic material that becomes an oxygen ion conductor at high temperatures.

2. How Does Limiting the Current Zirconia Oxygen Sensor Work?

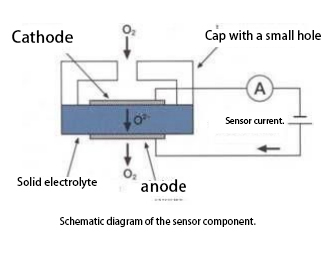

The limiting current type zirconia oxygen sensor is based on solid electrolytes and is widely used in automotive exhaust gas analysis and industrial process control. Its operating principle relies on the ionic conductivity of the zirconia electrolyte. When the zirconia electrolyte operates at high temperatures, oxygen ions can move within it, generating a current that is proportional to the oxygen concentration in the gas.

Figure- limiting current type zirconia oxygen sensor working principlle

Specifically, the basic structure of a zirconia sensor consists of two layers of electrodes and a layer of zirconia electrolyte. The sensor operating process is as follows: at high temperatures, the zirconia electrolyte becomes conductive. When oxygen passes through the sensor, oxygen molecules dissociate into oxygen ions on the surface of the electrolyte. These oxygen ions migrate within the electrolyte, generating a current that is related to the oxygen concentration in the gas. By measuring the current intensity, the oxygen concentration in the gas can be determined.

3. Features of Limiting Current Zirconia Oxygen Sensor

The limiting current zirconia oxygen sensor is a specialized form of zirconia sensor, distinguished by its ability to operate under limiting current conditions.

- High-temperature stability: It can maintain good stability under high-temperature conditions, making it suitable for measuring flue gases at elevated temperatures.

High sensitivity: Capable of detecting very low concentrations of oxygen, making it ideal for precise measurements in complex flue gases. - Strong anti-interference capability: Effectively resists interference from other gases in high-temperature flue gases, providing accurate measurement results.

The humidity in flue gases can be calculated from the difference between the second and first limiting currents. Therefore, a humidity meter based on the limiting current zirconia principle has a significant advantage over other types of humidity meters. Since its primary function is to measure oxygen, and measuring humidity requires measuring oxygen, users do not need to install a separate oxygen analyzer. A single humidity meter can provide both measurements simultaneously.

4. Isweek Limiting Current Type Zirconia Oxygen Sensor SO-E2-250/960

Humidity meters based on the limiting current zirconia principle have distinct advantages. The SO-E2-250/960 limiting current oxygen sensor, introduced by Winsen, has been widely applied in the field of flue gas analysis. It features an internal ceramic electrode that is more resistant to corrosion, a compact size, and high measurement accuracy. The sensor can be used in flue gas temperatures ranging from ambient to 350°C, offering a high cost-performance ratio. Even in high-temperature flue gases, the sensor maintains good stability and accuracy.

Conclusion

The application of limiting current zirconia oxygen sensors in measuring the humidity of high-temperature flue gases from stationary pollution sources is of great significance. Their high-temperature stability, high sensitivity, and strong anti-interference capabilities make them an ideal choice for flue gas humidity measurement. Although there are some technical challenges, improvements in materials, advancements in data processing technologies, and the development of integrated monitoring systems can effectively enhance their performance in practical applications. As environmental regulations become stricter and technology advances, limiting current zirconia oxygen sensors is expected to play a greater role in future environmental monitoring, contributing to the protection of the environment and public health.

Good news for all us