Industrial processes such as coal combustion, waste incineration, and boiler operations generate flue gases containing toxic pollutants like carbon monoxide (CO) and nitric oxide (NO). These gases pose severe risks to human health and environmental safety:

Carbon Monoxide (CO): Binds to hemoglobin 240x faster than oxygen, causing tissue hypoxia. Acute exposure leads to headaches, coma, or death, while chronic exposure increases cardiovascular risks.

Nitric Oxide (NO): Irritates the respiratory system, disrupts cardiovascular function, and damages neural cells at high concentrations.

Effective monitoring of these gases is essential to comply with environmental regulations, protect worker safety, and optimize industrial processes.

Alphasense Electrochemical Sensors: Precision in Flue Gas Analysis

Alphasense’s CO-AE and NO-AE electrochemical sensors are engineered for high-performance gas detection in harsh industrial environments. Their advanced technology addresses the challenges of accuracy, stability, and cross-interference in flue gas monitoring.

1. Carbon Monoxide Sensor: CO-AE

Technical Specifications

-

Measuring Range: 0–10,000 ppm

-

Resolution: 5 ppm

-

Operating Conditions: -30°C to 50°C, 15–90% RH

-

Key Features:

-

High sensitivity and linear low-concentration output.

-

Anti-interference design (resists H₂S, NO₂, Cl₂, NO, SO₂, NH₃, H₂).

-

Integrated dust/water droplet filtration membrane.

-

Applications:

-

Real-time CO monitoring in coal-fired power plants.

-

Emission control in chemical manufacturing.

-

Safety systems for automotive exhaust testing.

2. Nitric Oxide Sensor: NO-AE

Technical Specifications

-

Measuring Range: 0–5,000 ppm

-

Resolution: 1 ppm

-

Operating Conditions: -20°C to 50°C, 15–90% RH

-

Key Features:

-

Exceptional selectivity against CO, H₂S, SO₂, and NH₃.

-

Stable performance in high-humidity environments.

-

Rapid response to NO concentration changes.

-

Applications:

-

NO detection in industrial boiler emissions.

-

Waste incineration plant compliance monitoring.

-

Occupational safety in metal processing facilities.

Why Alphasense Sensors Excel in Flue Gas Monitoring

1. Wide Detection Range

Alphasense sensors outperform competitors with their extended measuring ranges:

-

CO-AE: Captures CO levels from 5 ppm to 10,000 ppm, ideal for both low-level leaks and high-concentration industrial emissions.

-

NO-AE: Detects NO from 1 ppm to 5,000 ppm, ensuring compliance with strict emission standards.

2. Enhanced Stability and Durability

-

Temperature Resilience: Operates reliably in extreme conditions (-30°C to 50°C), crucial for outdoor or unregulated industrial settings.

-

Long Lifespan: Robust construction minimizes drift, reducing calibration frequency and maintenance costs.

3. Anti-Interference Technology

Proprietary filtration membranes and electrode designs eliminate cross-sensitivity to common flue gas components like H₂S and SO₂. This ensures accurate readings even in complex gas mixtures.

Industrial Applications of Alphasense Sensors

1. Coal-Fired Power Plants

Flue gases from coal combustion contain high CO and NO levels. Alphasense sensors enable:

-

Real-time emission tracking to meet EPA or EU Industrial Emissions Directive (IED) limits.

-

Combustion optimization, reducing fuel consumption and CO₂ output.

2. Waste Incineration Facilities

Gases from incinerators include toxic NO and CO. These sensors help:

-

Monitor gas scrubbing systems to prevent pollutant release.

-

Safeguard workers from exposure during maintenance.

3. Industrial Boilers

Improper combustion in boilers generates hazardous CO. Alphasense CO-AE sensors:

-

Provide instant alerts for incomplete combustion.

-

Support predictive maintenance to avoid unplanned downtime.

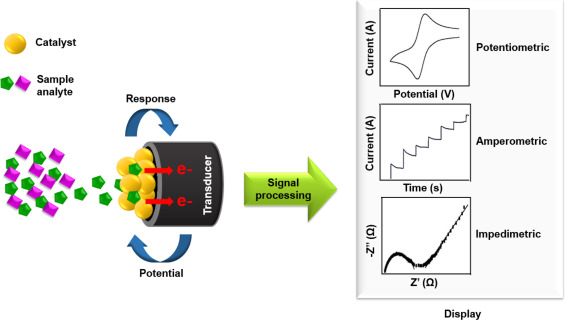

The Science Behind Electrochemical Gas Detection

Electrochemical sensors operate via redox reactions:

-

Gas Diffusion: Target gases (e.g., CO, NO) enter through a permeable membrane.

-

Electrochemical Reaction: Gases react at the working electrode, generating a current proportional to their concentration.

-

Signal Output: The current is converted into a measurable voltage, providing real-time data.

Alphasense optimizes this process with:

-

Advanced Catalysts: Enhance reaction efficiency for faster response times.

-

Temperature Compensation Algorithms: Maintain accuracy across fluctuating conditions.

Future Trends in Flue Gas Monitoring

-

IoT Integration: Wireless sensors for remote, cloud-based emission tracking.

-

Multi-Gas Detection: Single devices capable of measuring CO, NO, SO₂, and particulate matter.

-

AI-Powered Analytics: Predictive models to forecast emission trends and optimize processes.

Conclusion

Alphasense’s CO-AE and NO-AE electrochemical sensors are indispensable tools for industrial flue gas monitoring. Their precision, durability, and anti-interference capabilities make them ideal for power generation, waste management, and heavy industries. By adopting these sensors, companies can achieve regulatory compliance, enhance operational safety, and contribute to global environmental protection efforts.