What is the problem that needs to be solved?

Building Management Systems (BMS), Demand-Controlled Ventilation (DCV) systems and Indoor Air Quality (IAQ) equipment often require installation of wirelessly-connected, battery-powered CO2 sensor devices in environments where mains power is not easily accessible or where its provision is not economically viable; such as with building technology upgrades and retrofitting.

The requirement to measure is being driven by two key factors – legislation and economics. Many countries have either set or are in the process of setting maximum allowable levels of CO2 in school classrooms, hospitals, public buildings, hotels and in the workplace. For example, the US Occupational Safety and Health Administration (OSHA) has set a Permissible Exposure Limit (PEL) for CO2 of 5,000 parts per million (ppm) (or 0.5%) over an 8-hour workday. They report that exposure to levels of CO2 above this can cause problems with concentration, an increased heart rate, breathing issues, headaches and dizziness, (United Stated Department of Labor, n.d).

Changing the air in a building to regulate CO2 levels has an energy cost – especially if incoming air must also be heated or cooled. This is particularly relevant at night-time and weekends, when buildings may not be fully occupied. DCV or IAQ equipment are increasingly incorporating CO2 monitors so that the air change is controlled by the need to reduce the CO2 levels.

What are the requirements for the CO2 sensor?

CO2 monitoring systems often need to be installed in locations where access to mains power is limited, or its provision is costly. The ability to be able to power the CO2 sensor for long periods of time from a battery or from energy generated using harvesting techniques is highly desirable. To reduce maintenance costs, users want the ability for the CO2 sensor to operate autonomously for up to 10 years without any user intervention.

Energy harvesting is a technique used to collect very small amounts of ambient energy to power wireless devices. Assuming the power consumption of the CO2 sensor and wireless network interface is low enough, ambient energy present in the environment can be sufficient to power remote monitoring equipment with an almost unlimited lifetime.

How is CO2 sensor enabled?

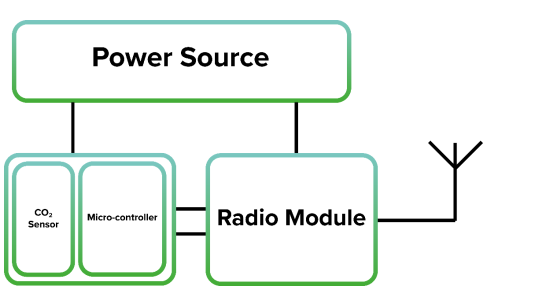

A wireless CO2 sensor suitable for use in IAQ systems consists of four major building blocks, a CO2 sensor, microcontroller, low power radio module and a power source.

Conventional CO2 sensors work by illuminating the gas using a filtered incandescent light source and measuring the absorption using a light detector. However, the power consumed using this type of CO2 sensor is too high to make it usable in a portable, or low power application. The cost of facilities management required to frequently change batteries is impractical and too expensive.

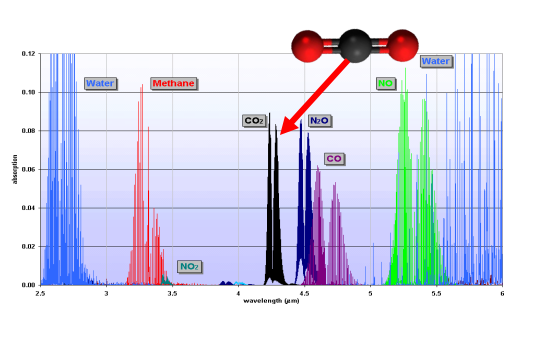

Regardless of the source of illumination, measurement of the CO2 level is determined using the Beer-Lambert law. Beer-Lambert’s law states that the loss of light intensity when it propagates in a medium is directly proportional to intensity and path length. CO2 molecules absorb infrared radiation at a wavelength of around 4.3 microns (chemguide, n.d).

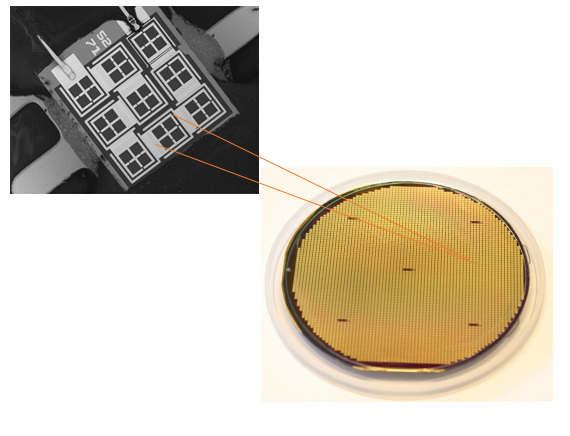

Gas Sensing Solutions’ CO2 sensors use a solid state, ultra-low power LED light source. This type of light source has a number of advantages, particularly for low power applications.

The CO2 gas is strongly absorbed by mid-IR 4.25um light. GSS manufactures its own LEDs, which have been specifically designed to emit a narrowband of light centred at 4.25um. This means little or no energy is consumed generating light of wavelengths that are unused. This is very different from a typical incandescent light source, which is intrinsically inefficient as it generates broadband light, most of which is wasted.

Solid-state sensors such as those from GSS also have a much longer lifetime, typically measured in years, which along with the long run time dramatically reduce lifetime maintenance costs.

GSS’s ultra-efficient LED light source can also be switched on and off rapidly, much faster than conventional incandescent sources. The GSS LEDs can switch on and become usable for CO2 measurement within seconds. This enables the user to take readings quickly before shutting down the module, thus minimising overall power consumption.

Introducing the CozIR-Blink

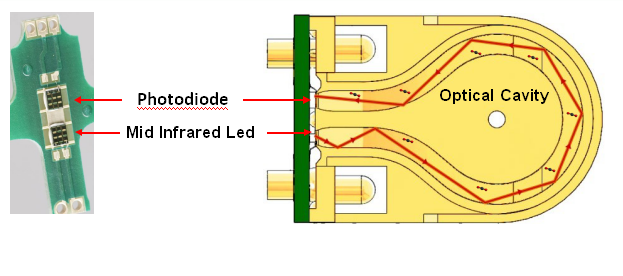

GSS has recently designed a new ultra-low power CO2 sensor module specifically for low power applications. The module consists of four major functions, a mid-IR LED, a photodiode, an optical light path and a microcontroller.

Light from the LED is injected into the optical cavity, which contains the CO2 gas that has been allowed to enter it through a hole on the top surface. The light that passes through the optical cavity is detected by the photodiode. The signal from the photodiode is digitised by the microcontroller and compared with a reference level stored in memory. The microcontroller can then calculate the level of CO2 in the optical cavity.

The introduction of the CozIR-Blink allows users to reduce power consumption of the CO2 measurement to unprecedented levels. The CO2 module can be power cycled, allowing the user to wake up the unit from a dormant state, take a reading, and then power it down completely again.

The sensor module has a READY pin that indicates valid data is available, approximately 3.2s after application of power. Data is available to be read out when the sensor module outputs a valid READY pulse whilst power is maintained.

The sensor interfaces to the host controller using the UART or I2C interface. In its simplest form, thesensor is accessed by the I2C Master requesting data from the sensor once the READY pin is pulsed high. The Master selects the CozIR Blink and reads out data in 2 bytes from the appropriate register.

In a typical application such as HVAC where the user might want to take a reading every minute, the power requirement can be as low as 417uW per reading for the CozIR Blink. Power consumption can be reduced even further by setting the unit to reduce measurement accuracy, or by increasing the measurement interval.

The CozIR Blink has been designed to run autonomously and requires no in use adjustment over the lifetime of the sensor. The sensor is calibrated before shipping with a 400ppm zero point. During use, the sensor can be programmed to automatically recalibrate with a duty cycle defined by the user. This ensures the sensor can operate optimally over the lifetime of the product. Accuracy is further improved by allowing the user to configure the sensor for the effects of altitude.

The CozIR Blink automatically starts a measurement sequence when power is applied to the module.The sensor module flags that a CO2 measurement is available and is designed to be powered downafter the measurement is read out.

Conclusion

GSSs new CozIR-Blink has been designed specifically to address applications that require measurement of CO2 combining very low power consumption with high accuracy. This ultra-low power CO2 sensor can be powered from a small battery, solar panel or other energy harvesting device, with enough power left over for a wireless data and control connection. This makes it ideal to address the emerging requirements for low cost distributed Building Management Systems(BMS), Demand-Controlled Ventilation (DCV) and Indoor Air Quality (IAQ) systems.

I used to be recommended this website by way of my cousin. I’m not certain whether this publish is written via him as nobody else understand such detailed approximately my trouble. You’re incredible! Thank you!