Why Oxygen Control Matters in Anaerobic Environments

Anaerobic microorganisms—organisms that thrive without oxygen—are among Earth’s oldest life forms, evolving billions of years before photosynthetic organisms oxygenated the atmosphere. Today, they play pivotal roles in:

-

Biotechnology: Producing antibiotics (e.g., clindamycin) and biofuels.

-

Biogas Production: Converting organic waste into renewable energy through anaerobic digestion.

-

Bioremediation: Degrading environmental pollutants like chlorinated solvents in contaminated soils.

-

Food Industry: Enabling cheese, yogurt, and sourdough bread fermentation processes.

-

Medical Research: Shaping gut microbiome studies and treatments for inflammatory bowel disease.

-

Ecology: Breaking down organic matter in wetlands and deep-sea hydrothermal vents.

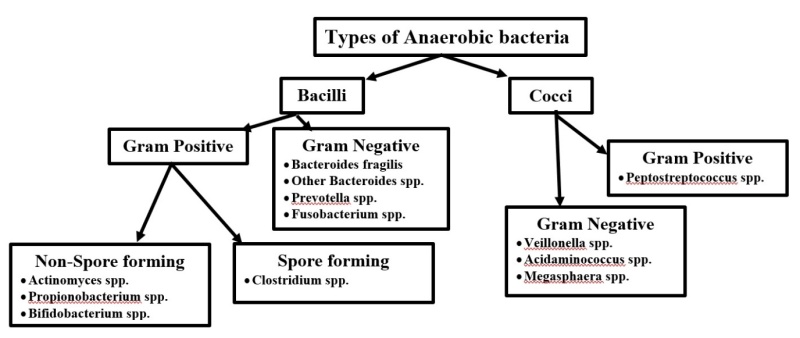

However, Clostridium and Bacteroides cannot survive even trace oxygen exposure. This is where anaerobic chambers—sealed, oxygen-free workstations—become critical. These chambers protect sensitive microbes by simulating Earth’s primordial anoxic conditions while enabling precise scientific observation.

Types of Anaerobic Chambers

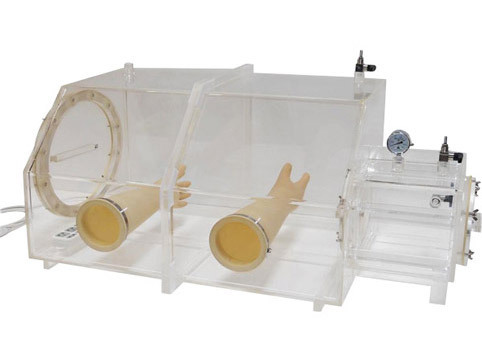

Anaerobic chambers (also called gloveboxes) are designed to maintain oxygen levels below 0.1 ppm—equivalent to 1 oxygen molecule per 10 million inert gas molecules. These systems vary in design to suit diverse applications:

1. Common Anaerobic Chambers Types

-

Portable Chambers: Compact, mobile units for fieldwork or temporary experiments.

-

Stationary Chambers: Large-scale systems for industrial bioreactors or high-throughput labs.

-

Glovebox Chambers: Feature integrated gloves for direct sample handling in oxygen-free conditions.

-

Compartment Chambers: Multi-zone designs for parallel experiments under controlled atmospheres.

2. Core Components of Anaerobic Chambers

-

Anaerobic Workspace: Flooded with inert gases (e.g., nitrogen, hydrogen).

-

Transfer Airlock: Safely moves samples without oxygen contamination.

-

Catalytic Scavengers: Remove residual oxygen via palladium-catalyzed reactions.

-

Gas Monitoring System: Tracks oxygen levels in real time.

Why Oxygen is Toxic to Anaerobic Microbes

Despite their critical design, even advanced chambers face a fundamental challenge: the inherent toxicity of oxygen to anaerobic microbes. Anaerobic microbes lack enzymes like superoxide dismutase to neutralize reactive oxygen species (ROS). Even 0.5 ppm oxygen generates lethal ROS, damaging cell membranes and DNA. Traditional monitoring methods—like methylene blue strips—are unreliable due to:

-

Delayed Response: Slow color changes risk microbial death.

-

Subjectivity: Human interpretation errors.

-

No Quantification: Lack of precise oxygen concentration data.

Modern chambers solve these issues with real-time micro-oxygen sensors and automated gas purging. By integrating advanced monitoring, researchers ensure microbial survival while advancing applications from drug discovery to renewable energy.

Modern Oxygen Monitoring Solution

Advanced micro-oxygen sensors use galvanic cell technology to detect oxygen in real time:

-

Electrochemical Reaction:

-

Oxygen molecules diffuse through a membrane.

-

At the cathode (e.g., gold): O₂ + 2H₂O + 4e⁻ → 4OH⁻

-

At the anode (e.g., lead): Pb → Pb²⁺ + 2e⁻

-

Generates a current proportional to oxygen concentration.

-

-

Key Advantages:

-

Real-Time Alerts: Detect oxygen spikes within seconds.

-

Precision: Measure concentrations as low as 0.1 ppm.

-

Automation: Trigger nitrogen purges when O₂ rises.

-

Practical Tips for Maintaining Anaerobic Conditions

-

Seal Integrity Checks

-

Regularly inspect chamber gloves, seals, and airlocks for leaks using pressure tests.

-

-

Catalyst Maintenance

-

Replace palladium catalysts (used to bind residual oxygen with hydrogen) periodically.

-

-

Sensor Calibration

-

Calibrate oxygen sensors monthly using certified zero-oxygen gas.

-

A Note on Oxygen Sensor Solutions

For reliable oxygen monitoring, sensors like the PSR-12-223 combine cutting-edge technology with robust performance:

-

0–100% O₂ Range: Suitable for trace and high-concentration detection.

-

±2% Full-Scale Accuracy: Ensures data reliability.

-

7-Second Response: Critical for preventing microbial exposure.

-

18–24 Month Lifespan: Minimizes replacement costs.

-

12-Month Warranty: Quality assurance for lab and industrial use.

Ideal For:

-

Anaerobic chambers operating between 0°C–45°C.

-

Applications requiring compliance with FDA/ISO standards.

Conclusion

The pursuit of oxygen-free environments is more than a technical challenge—it’s a gateway to scientific breakthroughs. By mastering precise oxygen control, researchers unravel mysteries of ancient microbes and engineer life-saving therapies. Emerging sensor technologies are transforming anaerobic chambers into fail-safe systems, bridging ancient microbial mysteries to modern industrial breakthroughs. This progress doesn’t just advance microbiology; it redefines humanity’s ability to harness nature’s most elusive organisms. The next frontier? A world where oxygen’s invisible threats are not just managed, but conquered.