Imagine this: A chemical plant operator notices an unusual odor near storage tanks. Within minutes, workers experience dizziness. The culprit? An invisible toluene leak at 200ppm – enough to cause nervous system damage. This scenario underscores why choosing the right photoionization detector (PID) isn’t just technical nitpicking; it’s a frontline defense against volatile organic compound (VOC) hazards.

While all PIDs detect hazardous vapors, their performance varies dramatically. Select wrong, and you might miss critical leaks or drown in false alarms. This guide cuts through the complexity, explaining PID fundamentals while giving practical selection insights you can apply today.

OSHA’s investigation into Toluene leak in American

What is a PID Sensor?

A Photoionization Detector (PID) is a highly sensitive gas sensor that detects volatile organic compounds (VOCs) and some inorganic gases at concentrations as low as 1 part per billion (ppb). Unlike destructive detection methods, PID sensors use ultraviolet (UV) light to temporarily ionize gas molecules without altering their chemical structure. This allows:

-

Non-destructive analysis: Sampled air can undergo further testing

-

Broad detection range: Identifies >400 VOCs, including aromatics, ketones, and sulfides

-

Real-time monitoring: Delivers results in seconds versus lab-based methods

Industries from oil refining to environmental monitoring rely on PIDs for their unmatched combination of speed, sensitivity, and portability.

How Does a PID Sensor Work?

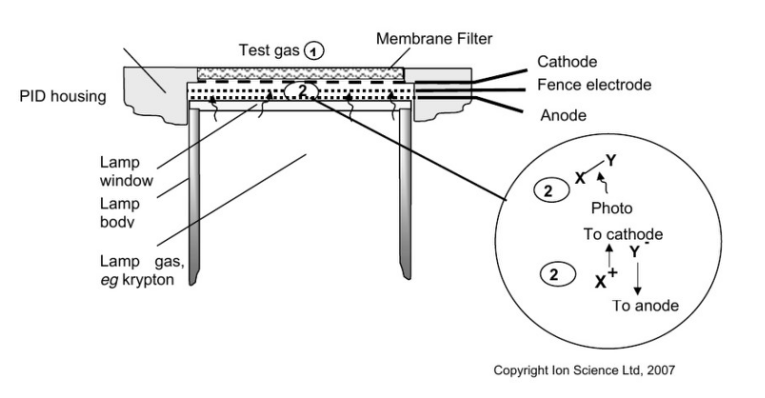

PID operation involves four key stages:

-

Gas Entry: VOCs enter the sensor chamber through a membrane filter.

-

UV Ionization: A high-energy UV lamp (typically 10.6 eV) emits photons that strike VOC molecules. If the photon energy exceeds the compound’s ionization potential (IP), electrons are ejected, creating positive ions and free electrons.

-

Charge Collection: An electric field between the anode and cathode attracts these ions, generating a tiny current.

-

Concentration Calculation: The current magnitude correlates directly with VOC concentration (e.g., 1 mV = 0.1 ppm isobutylene equivalent).

Critical Technical Notes:

-

UV Lamp Types: Krypton lamps (10.6 eV) detect most VOCs; xenon lamps (9.6 eV) offer selectivity for aromatics like benzene.

-

Ionization Limits: Compounds with IP > UV photon energy (e.g., methane at 12.6 eV) cannot be detected.

-

Humidity Compensation: Advanced sensors include a third electrode to filter noise from water vapor condensation.

What Are VOCs and Why Are They Detectable by PID?

Volatile Organic Compounds (VOCs) are carbon-based chemicals that readily evaporate at room temperature. They include:

-

Synthetic compounds: Solvents (toluene), plastics precursors (ethylene), and fuels

-

Naturally occurring terpenes: Pine scent (α-pinene), citrus oils

For a VOC to be detectable by PID, it must meet three criteria:

-

Contain <10 carbon atoms

-

Boiling point <250°C (marginally detectable up to 300°C)

-

Vapor pressure >0.00004 mbar at 25°C

This volatility ensures sufficient molecules are airborne for ionization. Common PID-detectable VOCs include benzene, acetone, and styrene; exceptions include propane and methane.

How to Choose the Right PID Sensor

Choosing the right PID sensor requires matching technical capabilities to your specific operational needs. Focus on these critical aspects:

1. Target Compounds and Concentrations

-

For low-level environmental monitoring (1-50 ppb VOCs like formaldehyde in schools), prioritize sensors with ppb-level sensitivity. The PID-AH5 delivers reliable 1 ppb detection even in humid conditions.

-

In industrial leak scenarios where toluene/xylene concentrations can spike to 4,000 ppm, the PID-A15 maintains accuracy without saturation.

-

When detecting chlorinated solvents (vinyl chloride in wastewater plants), the PID-AY5‘s 110 mV/ppm sensitivity outperforms standard sensors.

2. Environmental Operating Conditions

-

High-humidity sites (>90% RH) demand sensors like the PID-AH5 with humidity-compensated electrodes to prevent false readings.

-

Extreme cold environments (-40°C) require specialized designs such as the PID-A1‘s frost-resistant construction for Arctic operations.

-

All discussed sensors carry ATEX/IECEx certifications for hazardous zone deployment.

3. Power and Portability Needs

-

Battery-operated devices benefit from the PID-AH‘s 3.2-10V wide voltage range, ensuring stable performance during extended field use.

-

Fixed monitoring stations can leverage higher-power models like the PID-AR5 with Ethernet/CAN bus outputs for continuous data streaming.

Sensor Solutions That Actually Solve Problems

Each sensor addresses distinct detection scenarios with engineered solutions:

-

Ultra-trace detection: The PID-AH5 combines 1 ppb sensitivity with humidity resistance – critical for urban air quality stations during monsoon seasons.

-

Emergency response: With its <3-second response time and low power consumption, the PID-AH provides reliable readings in portable detectors during critical incidents.

-

Industrial safety: The PID-A15 handles sudden 4,000 ppm solvent leaks in chemical plants, preventing sensor overload during accidents.

-

Extreme environments: For Arctic pipeline monitoring, the PID-A1 operates reliably at -40°C while detecting methane surges up to 6,000 ppm.

-

Research applications: Laboratories requiring sub-ppb precision utilize the PID-AR5‘s speciation capabilities for air quality studies.

-

Chlorinated VOC detection: Wastewater facilities rely on the PID-AY5‘s enhanced sensitivity for tracking vinyl chloride at low concentrations.

Essential Maintenance Protocols

Proper upkeep ensures long-term accuracy:

-

Calibration: Perform quarterly using 10 ppm isobutylene gas. For ppb-level sensors like the PID-AH5, include 100 ppb validation checks.

-

Lamp replacement: Schedule every 6,000 operational hours (approximately 10 months of continuous use).

-

Contamination prevention:

-

Clean electrode assemblies quarterly with isopropyl alcohol

-

Replace inlet filters monthly in dusty environments

-

Avoid silicone-based sealants near sensors

-

-

Performance verification: Conduct bump tests before critical deployments

Conclusion: Strategic Sensor Selection

Effective VOC monitoring hinges on three operational questions:

-

What concentration ranges require detection? (ppb vs ppm)

-

Which specific compounds pose risks in your environment?

-

What physical conditions will the sensor encounter?

Whether monitoring formaldehyde in classrooms or preventing chemical plant incidents, precise sensor matching transforms invisible threats into actionable data. By aligning technical specifications with real-world requirements, you create robust protection against VOC hazards.

For further guidance: Consult our detection specialists for application-specific recommendations.