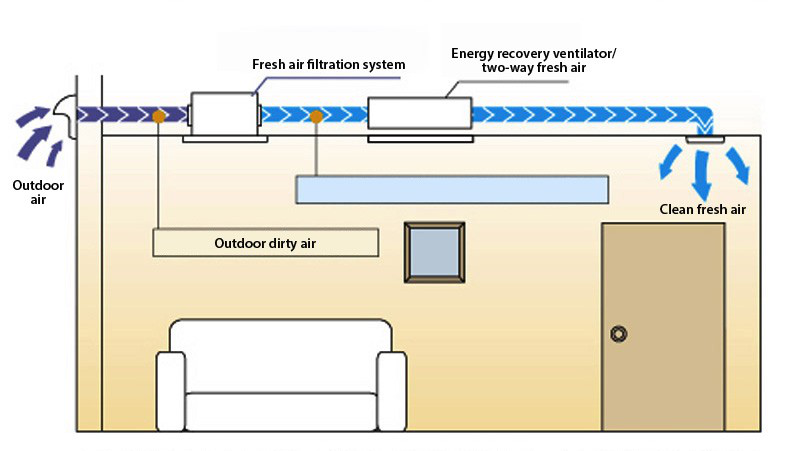

A fresh air system is an independent air processing system consisting of a supply system and an exhaust system. These systems are categorized into ducted (with pipelines) and ductless (without pipelines) configurations. Ducted systems, which include a fresh air ventilator and pipe fittings, are ideal for industrial facilities or large offices due to their complex engineering. Ductless systems, requiring only a ventilator, are better suited for residential use owing to their simple installation. Both systems introduce fresh air indoors while expelling stale air outdoors. The concept dates back to 1935, when Alston Ceeyee invented the first heat exchange equipment capable of filtering polluted air, laying the foundation for modern fresh air systems.

The Role of Gas Sensors in Air Quality Monitoring

Gas sensors are critical devices that convert gas concentrations into measurable electrical signals. They filter impurities, dry samples, and eliminate interfering gases to ensure accurate readings. Today, sensors are widely used in civil, industrial, and environmental applications. Common types include:

-

Semiconductor sensors

-

Solid electrolyte sensors

-

Contact combustion sensors

-

Electrochemical sensors

-

Photoelectric sensors

In fresh air systems, sensors for CO2, PM2.5, formaldehyde, VOC, temperature, and humidity enable real-time air quality monitoring. Below are ISweek‘s top recommendations for each category:

Recommended Gas Sensors for Fresh Air Systems

1. CO2 Sensors

ZG09 NDIR CO2 Sensor

-

Key Features:

-

Dual-beam NDIR technology for long-term stability.

-

Ideal for indoor air quality (IAQ), greenhouses, HVAC, and demand-controlled ventilation (DCV).

-

-

Applications:

-

Real-time CO2 monitoring in residential and commercial buildings.

-

2. PM2.5 Sensors

PDSM010 PM2.5 Sensor

-

Key Features:

-

Detects particles as small as 1㎛ (dust, pollen, microorganisms, smoke).

-

PWM output with noise-filtering algorithms for stable performance.

-

No manual calibration points, preventing user tampering.

-

-

Applications:

-

Air purifiers and indoor air quality monitors.

-

TF-LP01 Laser PM2.5 Sensor

-

Key Features:

-

Laser scattering technology for high accuracy and repeatability.

-

Real-time response and ultra-quiet operation.

-

Factory-calibrated and 100% tested.

-

-

Applications:

-

Smart home air quality systems.

-

3. Temperature & Humidity Sensors

HTU21D Digital Sensor

-

Key Features:

-

DFN packaging (3x3x1mm) for compact designs.

-

I²C digital output with programmable resolution (8–14 bit).

-

Low power consumption and cost-effective for OEMs.

-

-

Applications:

-

HVAC systems, medical devices, and consumer electronics.

-

HTG3515CH Analog Sensor

-

Key Features:

-

Linear voltage output for humidity and NTC output for temperature.

-

Designed for precise, reliable measurements.

-

-

Applications:

-

Industrial control and automotive systems.

-

4. VOC Sensors

VOC-MF1, VOC-PF1, VOC-AF1 Sensors

-

Key Features:

-

Detect 10–50 ppb of total VOCs (e.g., formaldehyde, toluene).

-

P-type metal oxide technology with wide dynamic range and humidity resistance.

-

Operate in constant temperature/pressure modes or temperature cycling (400°C–525°C).

-

-

Applications:

-

Air quality monitors and smart ventilation systems.

-

Smart Control in Fresh Air Systems

Modern fresh air systems use sensor data to automate airflow adjustments. For example:

-

Sensors detect rising CO2 or PM2.5 levels.

-

Data is transmitted to a central processor.

-

The system adjusts fan speed or activates filters to maintain optimal air quality.

This automation ensures energy efficiency—systems operate only when needed—while providing users with clean, fresh air.

Global Applications of ISweek Sensors

ISweek‘s CO2, PM2.5, VOC, and temperature/humidity sensors are trusted by manufacturers worldwide for:

-

Residential Systems: Smart homes with air quality alerts.

-

Commercial Buildings: Offices and hospitals require compliance with air standards.

-

Industrial Facilities: Factories needing pollutant control.

Imagine this:

When you wake up in the morning, the smart curtain unfolds to let sunshine in, and fresh air ventilator bring you the sweet breeze outside. It’s for sure that you will enjoy a nice day.

The fresh air system works intelligently: when the atmosphere changes, sensors transfer the measured concentration value into digital or analog signals and send them to data the collector, and then the data is sent to the central processor, which controls each controller to turn on or off to adjust wind strength and filter the air.