Methane is a flammable gas, and leaks can pose serious safety and environmental risks. This colorless and odorless substance (CH4) is challenging to detect without specialized methods, such as the use of odorants like mercaptan and gas detectors. Moreover, Methane is commonly utilized as a fuel for heating and electricity generation, as well as a raw material in the chemical industry.

For this reason, methane gas safety solutions that incorporate gas sensors are essential for monitoring, identifying, and controlling leak levels early on. These systems help ensure safety in both industrial and residential environments.

In this guide, we’ll dive into how methane gas detectors work, the methods available for methane detection, and the innovative products that are revolutionizing the field.

What is A Methane Gas Detector?

A methane gas detector is a specialized device used to detect the presence of methane in the air. These detectors help identify leaks, monitor gas concentrations, and trigger alarms when levels exceed safety thresholds. Methane gas detectors are essential in industries such as oil and gas, natural gas transportation, agriculture, and environmental monitoring.

Why is Methane Gas Detection Important?

Methane gas leaks can have far-reaching consequences:

- Safety Risks: Methane is highly combustible. A small leak near an ignition source can lead to catastrophic explosions.

- Environmental Concerns: Methane is a potent greenhouse gas, contributing significantly to climate change.

- Economic Impact: Uncontrolled leaks can lead to lost resources, fines, and damaged infrastructure.

Using reliable methane gas detectors ensures early detection, allowing for quick mitigation and minimizing these risks.

Methods for Detecting Methane Gas

Detecting methane gas can be approached in various ways, each suited for different environments or purposes:

1. Detecting Methane Gas without Professional Equipment

Odor Detection

Methane itself is odorless, but in industrial and domestic settings, it’s often mixed with mercaptan, a sulfur compound that gives it a distinctive smell similar to rotten eggs. If you detect this smell, it could indicate a methane leak.

Visual Signs

In some cases, methane leaks can lead to visible signs like wilting vegetation, especially around pipelines or wellheads, due to the displacement of oxygen.

Miners’ Traditional Methods

Historically, miners used canaries to detect methane due to their sensitivity to toxic gases. Modern equivalents include sniffer techniques or placing animals in areas where methane might accumulate, though this is now largely replaced by electronic sensors.

2. Use of Gas Detectors

Gas Detectors monitor gas concentrations, and trigger alarms when levels exceed safety thresholds.

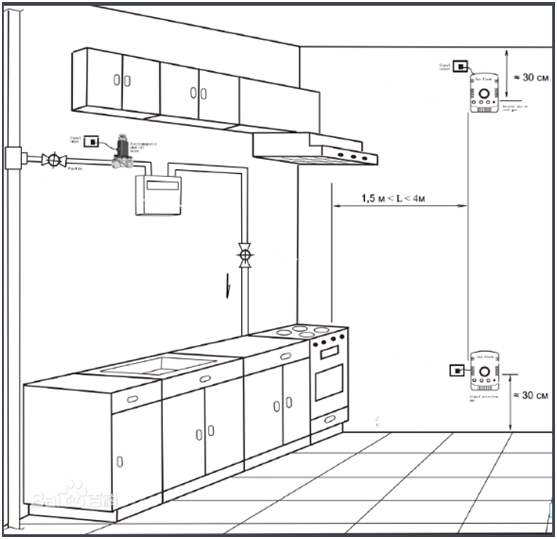

Fixed Gas Detectors

These are installed in areas where methane might accumulate, such as near the ceiling since methane is lighter than air. They provide continuous monitoring and alert when methane levels reach dangerous concentrations.

Portable Gas Detectors

Ideal for pinpointing leaks in specific locations. These devices can be carried around and are useful for both industrial and home settings. They often use laser technology for detection, measuring methane down to very low concentrations.

Electronic Leak Detectors

These devices can detect small amounts of methane and other gases. They usually come with visual and audible alarms to alert users of gas presence. An excellent example is the Figaro TGS8410, a state-of-the-art methane gas sensor that combines MEMS technology with a metal oxide semiconductor layer for high sensitivity and selectivity to methane gas. Its compact size and low power consumption make it suitable for portable and battery-operated devices, ensuring reliable detection in both residential and industrial environments.

Combustible Gas Pellistors

Combustible gas pellistors are gas sensors that detect combustible gases and vapors in the air. They can detect a wide range of flammable gases, including methane, propane, butane, hydrogen, and more. Combustible gas pellistors are particularly valuable in industrial settings and safety applications where the presence of explosive gases, like methane, poses a risk. The CH-A3 Combustible Gas Pellistor, for instance, is notable for its innovative approach. It boasts high-quality detection capabilities and remarkable resistance to poisoning. With its certified flameproof chamber and sturdy build, it’s well-suited for environments where both safety and precision are paramount.

The Principle of Sensing

1. Infrared Technology NDIR

Infrared sensors are particularly effective because they are not affected by oxygen levels, making them suitable for a wide range of applications from industrial monitoring to environmental surveillance. They detect methane by analyzing the light spectrum it absorbs.

2. Scientific Methods

For precise measurements, gas chromatography or spectroscopy can be used in controlled settings like labs to detect methane and measure its concentration accurately.

3. Pellistor Sensor

The TGS8410 methane gas sensor, with its low power consumption and advanced MEMS design, exemplifies the innovation in methane detection technology. Its durability and precision make it a key tool for industries seeking effective solutions for methane monitoring and safety.

Features of A Reliable Methane Gas Detector

When choosing a methane gas detector, consider the following features:

- Sensitivity: The ability to detect methane at very low concentrations.

- Selectivity: Differentiating methane from other gases to minimize false alarms.

- Durability: Resistance to harsh environments, ensuring long-term reliability.

- Portability: Compact and lightweight designs for field use.

- Power Efficiency: Low power consumption for continuous monitoring, especially in portable or battery-operated devices.

- Explosion-Proof and Certification: Compliance with explosion-proof standards and certified for use in hazardous environments, ensuring safety in high-risk applications.

Applications of Methane Gas Detector

Methane sensors are crucial in ensuring safety and efficiency across various sectors, particularly in residential and industrial applications.

1. Residential Applications

In homes and other residential settings, methane sensors are commonly integrated into gas leak detectors and safety systems to prevent potential hazards caused by methane leaks from natural gas appliances such as stoves, heaters, and boilers. These sensors provide real-time monitoring and alerts, ensuring the early detection of leaks to prevent explosions, fires, or health risks caused by prolonged exposure. Compact, portable methane detectors are also gaining popularity for personal and family use, enhancing safety in everyday life.

2. Industrial and Mining Applications

In industrial and mining operations, methane detection is critical for preventing workplace accidents. In underground mining, particularly in coal mines, methane is a common byproduct of extraction processes and poses a high risk of explosion. Methane sensors installed in mining equipment or ventilation systems monitor gas concentrations continuously, providing alerts when levels exceed safety thresholds.

In addition, methane sensors are extensively used in industrial facilities such as oil and gas processing plants, refineries, and chemical manufacturing. These sensors help monitor pipelines, storage tanks, and confined spaces to prevent leaks, ensure environmental compliance, and maintain worker safety. The real-time data provided by advanced sensors allows for proactive maintenance and immediate response to potential hazards, minimizing downtime and costly damages.

How to Install and Use A Methane Gas Detector?

1. Site Assessment

Identify high-risk areas for methane accumulation, such as pipelines, storage tanks, or confined spaces.

2. Selection of Detectors

Choose a methane gas detector tailored to your needs, such as fixed detectors for continuous monitoring or portable devices for inspections.

3. Proper Installation

Position detectors at appropriate locations, typically near the ceiling where methane tends to rise.

4. Regular Maintenance

Ensure detectors are calibrated and serviced periodically to maintain accuracy and functionality.

The Future of Methane Detectors: New Tech and Uses

Drones and Remote Sensing

For larger areas like oil and gas facilities or agricultural lands, drones equipped with methane sensors can detect emissions. Similarly, satellite technology is advancing to monitor methane from space, providing data on emissions from a broader perspective.

TD–LAS

Tunable Diode Laser Absorption Spectroscopy (TD-LAS) represents a cutting-edge technique for gas detection, offering unparalleled precision and sensitivity. By utilizing tunable diode lasers and laser absorption spectrometry, TD-LAS enables the measurement of methane concentrations at extremely low detection limits. Beyond concentration measurement, TD-LAS can assess temperature, pressure, velocity, and mass flux of the observed gas, making it the most widely used laser-based absorption method for quantitative gas analysis.

The AG-6-CH4-28M2 laser methane sensor exemplifies the practical application of TD-LAS technology. By harnessing the unique absorption characteristics of methane at the 1653.7 nm infrared “fingerprint spectrum,” this sensor provides highly accurate methane concentration readings. Its folded optical path design ensures a long absorption path, enhancing sensitivity and reducing interference from water vapor and other gases. With advanced low-temperature laser and photodetector components combined with a wide temperature compensation algorithm, the AG-6-CH4-28M2 performs reliably in diverse environments.

Featuring a standard thread mounting interface and communication protocol, this versatile sensor serves as a core component in methane detectors and monitors. It is ideal for detecting methane leaks and triggering alarms across a variety of applications, including underground spaces, the catering industry, industrial chemical facilities, and coal mines. Together, TD-LAS technology and innovations like the AG-6-CH4-28M2 are shaping the future of methane detection with enhanced precision, reliability, and adaptability.

TGS8410

The TGS8410 Methane Gas Sensor is a state-of-the-art solution for methane detection, combining efficiency, precision, and versatility. With an impressively low power consumption of just 0.087 mW, it is ideal for portable and battery-operated devices. Its advanced design ensures high sensitivity to methane while effectively filtering out interference from other gases, such as alcohol. The sensor’s compact size, measuring only 9.2 mm in diameter and 12.5 mm in height, allows for seamless integration into handheld and mobile equipment. Additionally, it boasts a long operational life of up to five years on a lithium-ion battery, reducing maintenance costs and enhancing reliability.

Designed with advanced MEMS (Micro Electro Mechanical Systems) technology, the TGS8410 sensor excels in applications such as portable methane detectors, wireless gas detection systems, leak detection in natural gas vehicles and pipelines, and residential or industrial gas leakage alarms. Its innovative features and dependable performance make it an essential tool for modern methane detection needs.

Conclusion

Methane gas leaks pose significant risks to safety, the environment, and operations. By using reliable methane gas detectors and adopting advanced technologies, industries can detect and mitigate leaks effectively.

For more information and product inquiries, visit Isweek‘s Product Page.