Global methane regulations are tightening rapidly, and industries worldwide must prioritize emission reduction to ensure both safety and environmental compliance. Methane (CH₄)—25 times more potent than CO₂ as a greenhouse gas—carries dual risks: immediate explosion hazards in industrial facilities and long-term climate damage from persistent leaks. This 2025 guide ranks the Top 10 Methane Sensors based on critical factors like accuracy, durability, and real-world performance. Whether securing oil refineries or tracking landfill emissions, uncover the technologies setting new standards for gas detection.

Why Methane Detection Matters?

Methane (CH₄) is a potent greenhouse gas, 25x more effective at trapping heat than CO₂. Leaks in industrial settings pose explosion risks, while agricultural and landfill emissions contribute significantly to climate change. Modern methane sensors combine advanced detection methods like NDIR (Non-Dispersive Infrared) and Catalytic Bead technologies to deliver precise, real-time data.

Key Features to Look for in Methane Sensors

Before diving into our 2025 recommendations, understand these critical factors:

- Detection Range: From 0-100% LEL (Lower Explosive Limit) for safety to ppm-level accuracy for environmental monitoring.

- Response Time: Faster sensors (<5 seconds) save lives in hazardous environments.

- Durability: Look for IP67-rated sensors resistant to dust, humidity, and corrosive gases.

- Calibration: Sensors with automatic drift compensation reduce maintenance costs.

Top 10 Methane Sensors for 2025

1. Figaro TGS 2611-E00 Methane Sensor

- Technology: Catalytic combustion

- Range: 500–10,000 ppm

- Best For: Residential gas leak detection

2. ISweek AG-2-CH4-MA2611(D) Enhanced Module

- Core Sensor: TGS 2611-E00 with ISweek optimization

- Key Advantages:

√ Integrated alcohol interference filter

√ Factory pre-calibrated for plug-and-play deployment

√ USART digital output for smart alarm systems - Recommended For: Smart home detectors requiring minimal setup

![]()

3. CH-A3 NDIR Methane Sensor

- Technology: Catalytic combustion

- Range: 0–100% LEL

- Best For: Explosion-proof industrial environments

4. ISweek AG-3-CHx-CHA3(D) Industrial Module

- Core Sensor: Enhanced CH-A3 integration

- Key Advantages:

√ Pre-calibrated for harsh environments (dust/humidity resistance)

√ UART output enables IoT-ready connectivity

√ Multi-gas detection (CH₄, LPG, H₂) - Recommended For: Mining/LNG facilities needing wireless monitoring

5. TGS8410 MEMS Methane Sensor

- Technology: MEMS

- Range: 1–25% LEL

- Best For: Portable/wireless gas detectors, natural gas vehicle/pipeline leak monitoring

- Key Advantage:Ultra-low power (0.087mW), 5-year battery operation, alcohol-resistant selectivity

6. Figaro TGS6814 Methane Sensor

- Technology: Catalytic combustion

- Range: 0–100% LEL

- Best For: Indoor air quality monitoring in HVAC systems

7. ISweek AG-3-CHx-M6814(D) Enhanced Module

- Core Sensor: Figaro TGS6814 with ISweek optimization

- Key Advantages:

√ Triple-Gas Detection: Reliably identifies CH₄, LPG, and H₂ with anti-poisoning resistance.

√ Harsh Environment Ready: Pre-calibrated for stable performance in high-humidity/chemical settings.

√ Plug-and-Play UART Output: Simplifies integration with HVAC control systems. - Recommended For: Commercial building air quality management

8. ISweek AG-6-CH4-H8012-L TDLAS Laser Methane Sensor

- Technology: TD-LAS

- Range: 0-100% VOL (CH4), detection from 0.15% VOL.

- Best For: Home kitchens and residential combustible gas detection.

- Key advantages:

√ High precision: Tunable Laser Absorption Spectroscopy (TD-LAS) with temperature compensation and stable control algorithms

√ Durability: Expected lifespan of over 10 years with calibration-free operation

√ Wide environmental adaptability: Operates effectively in a wide temperature range (-10 to 55°C) and humidity (0-95% RH).

√ Low Power Consumption: Consumes less than 300mW at 24°C

√ Compact design: 20g weight, UART output

9. ISweek AG-6-CH4-2842-100 Wide Temperature Laser Methane Sensor

- Technology: TD-LAS

- Range: 0-100% VOL (CH₄), detection from 0.15% VOL.

- Best For: Underground spaces, coal mining, industrial chemical plants, and explosion-proof environments.

- Key advantages:

√ Explosion-resistant stainless steel design (IP-rated structural protection)

√ Ultra-wide temperature operation (-40°C to 70°C) and humidity tolerance (0-99% RH)

√ High precision (±0.06% VOL error at 0-1% range) and rapid response (<15s T90)

√ 10+ year lifespan with calibration-free maintenance

√ Low power consumption (<30mA average current)

√ Anti-interference design for harsh industrial conditions.

10. Methane and Carbon Monoxide Sensor – TGS3870

- Technology: Micro-bead semiconductor with dual-heater voltage cycling

- Range: Methane (500–12,500 ppm), CO (50–1,000 ppm)

- Best For: Residential combo gas detectors

- Key Advantages:

√ Dual-gas detection (CH₄/CO) with low alcohol interference

√ Ultra-low power (38mW average)

√ Compact design and long lifespan

√ Cost-effective consumer-grade solution

How to Choose the Right Methane Sensor?

1. Define Your Application:

- Safety Compliance: Prioritize LEL (Lower Explosive Limit) sensors for explosive environments (e.g., CH-A3 NDIR Sensor for industrial plants).

- Environmental Monitoring: Opt for high-precision sub-ppm sensors like TDLAS models (e.g., AG-6-CH4-H8012-L for residential use).

- Dual-Gas Detection: For multi-threat scenarios, choose hybrid sensors (e.g., TGS3870 for CH₄/CO combo detection).

2. Assess Technical Requirements:

- Detection Range: Industrial settings (e.g., coal mining) demand wide-range sensors (AG-6-CH4-2842-100: 0–100% VOL).

- Response Time: Critical for fast leak detection (AG-6-CH4-2842-100: <15s T90).

- Environmental Adaptability: For extreme conditions (-40°C to 70°C), select ruggedized designs (e.g., AG-6-CH4-2842-020).

3. Evaluate Environmental Conditions:

- Harsh Environments: Use IP-rated, anti-interference sensors (e.g., AG-3-CHx-CHA3(D) for mining/LNG facilities).

- Humidity/Temperature: Opt for wide-range tolerance (0–99% RH, -40°C to 70°C) as seen in AG-6-CH4-2842-020.

4. Consider Long-Term Costs:

- Calibration-Free Designs: Reduce maintenance (e.g., AG-6-CH4-H8012-Lwith 10-year lifespan).

- Power Efficiency: Choose ultra-low-power MEMS sensors (e.g., TGS8410: 0.087mW for 5-year battery life).

- IoT Compatibility: Prioritize UART/USART outputs (e.g., ISweek EM3870B module for smart systems).

The Science Behind Methane Sensors

Methane detection leverages advanced technologies tailored to diverse operational needs. Here’s a breakdown of the core methodologies powering modern sensors:

1. Catalytic Combustion

- Principle: Methane reacts with oxygen on a heated catalytic bead, generating measurable resistance changes.

- Strengths:

√ Cost-effective and reliable for explosive environments.

√ Ideal for residential/commercial safety (e.g., Figaro TGS2611-E00 in gas leak detectors).

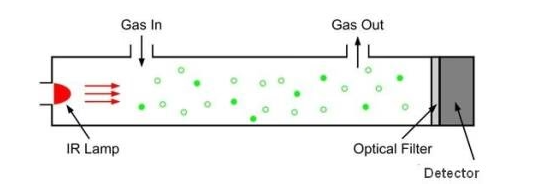

2. NDIR (Non-Dispersive Infrared)

- Principle: Detects methane’s unique infrared absorption at 3.3μm wavelengths.

- Strengths:

√ Immune to chemical poisoning, suitable for oxygen-free or dusty settings.

√ Trusted in explosion-proof industrial systems (e.g., CH-A3 NDIR Sensor for LNG facilities).

3. MEMS (Micro-Electro-Mechanical Systems)

- Principle: Miniaturized silicon chips measure thermal changes from methane interactions.

- Strengths:

√ Ultra-low power consumption (e.g., TGS8410 at 0.087mW for 5-year battery life).

√ Perfect for portable/wireless monitors in pipelines or natural gas vehicles.

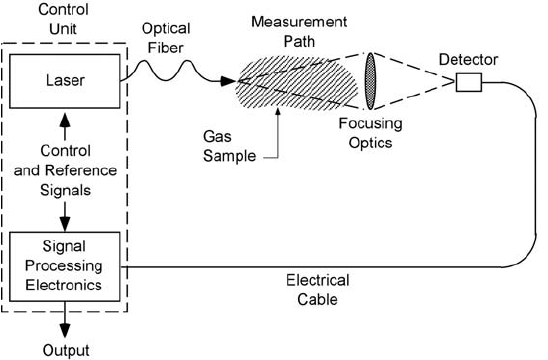

4. TDLAS (Tunable Diode Laser Absorption Spectroscopy)

- Principle: Laser beams target methane’s absorption lines (1.65μm or 3.3μm) for molecular-level precision.

- Strengths:

√ Sub-ppm accuracy (e.g., AG-6-CH4-2842-100 with ±0.06% VOL error).

√ Rugged, calibration-free designs for extreme environments (-40°C to 70°C).

√ Long lifespan (10+ years) in mining and chemical plants.

Innovative Hybrid Systems

1. Micro-Bead Semiconductor(e.g., TGS3870):

- Dual-heater voltage cycling enables simultaneous CH₄/CO detection with minimal alcohol interference.

- Optimized for residential combo detectors.

2. IoT-Enhanced Modules (e.g., EM3870B):

- Convert intermittent sensor signals to continuous outputs via embedded algorithms.

- Streamline integration with smart home/industrial systems.

These technologies empower methane sensors to excel across applications—from kitchen safety (TDLAS) to underground mining (NDIR)—ensuring precise, reliable detection while addressing power, environmental, and longevity challenges.

FAQs About Methane Sensors

Q: How often should I calibrate my methane sensor?

A: Most NDIR sensors need annual calibration; catalytic types require quarterly checks.

Q: Can methane sensors detect other gases?

A: Cross-sensitivity varies. For pure methane detection, choose NDIR with optical filters (e.g., ISweek AG-3-CHx-CHA3(D) Industrial Module).

Conclusion

Selecting a methane sensor in 2025 requires careful balancing of three factors:

- Precision: Detect leaks at ppm or LEL levels.

- Durability: Withstand harsh industrial conditions.

- Cost-Efficiency: Minimize calibration and maintenance expenses.

From battery-powered wireless detectors to explosion-resistant designs, next-gen sensors are transforming safety across energy, manufacturing, and environmental sectors. For customized solutions matching your operational needs, explore our sensor portfolio or consult our expert team today.