Scrubbing solution is added in the washing section during the fractional extraction process to eliminate impurities and fission fragments from the loaded organic phase. Various scrubbing solutions are used for different demands. ISWeek demonstrates how to detect the liquid level of scrubbing solutions in washing equipment before it gets too low.

Importance of Liquid Level in Washing Equipment

Liquid level is a critical factor affecting the performance of washing equipment. The effectiveness of the scrubbing solution is determined by its concentration, which in turn depends on the water level in the equipment. An excessive liquid level indicates that the fully automatic industrial washing machine is injecting too much water. This lowers the concentration and, consequently, the detergency of the scrubbing solution. Moreover, a high water level reduces the vertical height of the mechanical washing cylinder, weakening the beating force against clothes and reducing detergency. Therefore, setting the liquid level below 80% of the washing cylinder’s height is essential to maintain optimal performance and operational efficiency.

Liquid Level Control and Sensor Applications

Liquid level control is crucial in industrial production. Liquid detection and control devices are commonly seen on worksites. When liquid level sensors in the equipment trigger a high alarm (based on process specifications), the pump should activate to lower the liquid level. Conversely, when a low alarm is raised, pumping should be stopped to maintain the liquid level above the low alarm threshold.

Liquid level sensors have become popular among enterprises to measure both the liquid level in washing machines and the concentration of scrubbing solutions. These sensors output electrical signals that correspond to the height of the liquid. As modular circuits, they resist acid, moisture, vibration, and corrosion. With a constant current feedback circuit and internal protection, the maximum current in the module’s circuit is kept below 28mA, reliably protecting the power supply and secondary instruments. However, challenges such as high-viscosity liquids, wastewater containing impurities, foamy liquid, and corrosive liquid can complicate liquid level detection. In chemical industries, where corrosive liquids are common, interference from corrosion and vibration must be addressed. For such applications, ISWeek recommends industrial-grade photoelectric liquid level sensors/switches manufactured by SST (UK) – LLC200D324-003.

Optomax Industrial Series Optical Liquid Level Sensors

The Optomax Industrial Series Liquid Level Switches are designed to operate at industrial supply voltages and drive higher power loads directly. These microcontroller-based sensors are solid state, incorporating an infra-red LED and a phototransistor. When the sensor’s tip is in the air, the IR LED and phototransistor are optically coupled. Once the tip is immersed in liquid, the infra-red light escapes, and the sensor output changes state.

Key features of these sensors include:

- Versatility: Detects the presence or absence of almost any liquid type—oil or water based.

- Insensitivity to Ambient Light: Not affected by ambient light or foam when in air, nor by small bubbles when in liquid.

- Flexible Output: Available in various N and P type configurations, capable of sinking or sourcing up to 1A at supply voltages ranging from 4.5 to 15.4Vdc or 8 to 30Vdc. Configurable to output a high or low signal in either a wet or dry state.

- Robust Design: Equipped with housing threads for external mounting and available in two operating temperature ranges (Standard: -25°C to 80°C; Extended: -40°C to 125°C).

- Chemically Resistant Housing: Offered in Polysulfone, suitable for most applications, or Trogamid, typically used in food and beverage applications.

Benefits of these sensors include:

• High power

• Industrial supply voltage

• Direct load drive design

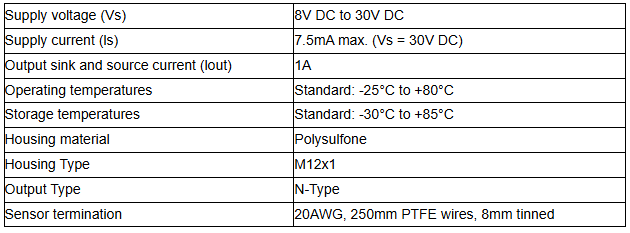

LLC200D324-003 Optomax Industrial Series Liquid Level Switches Technical Specifications

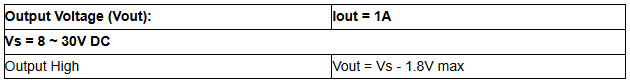

LLC200D324-003 Optomax Industrial Series Liquid Level Switches Output Values

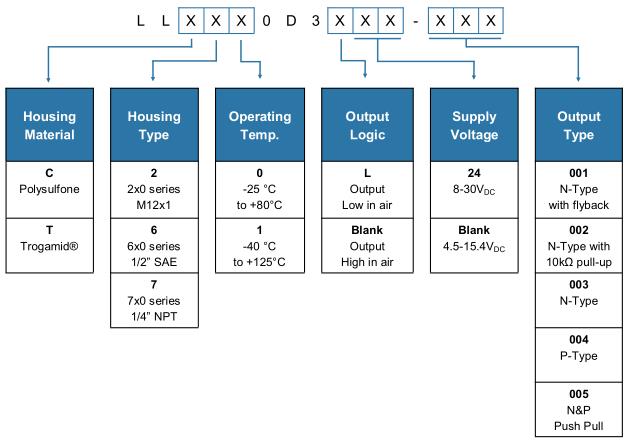

Optomax Industrial Series Liquid Level Switches Order Information

Generate your specific part number using the convention shown below. Use only those letters and numbers that correspond to the sensor and output options you require — omit those you do not.